Consultant and Designing

With a team of experienced business and engineers will offer the optimal solution for the project

Professional working process

Kalis applies a process that affirms professionalism and efficiency.

Superior product quality

Product quality is the top criterion for Kalis to affirm its leading position.

All-inclusive maintenance service

Kalis offers full-service and after-sales care.

Description

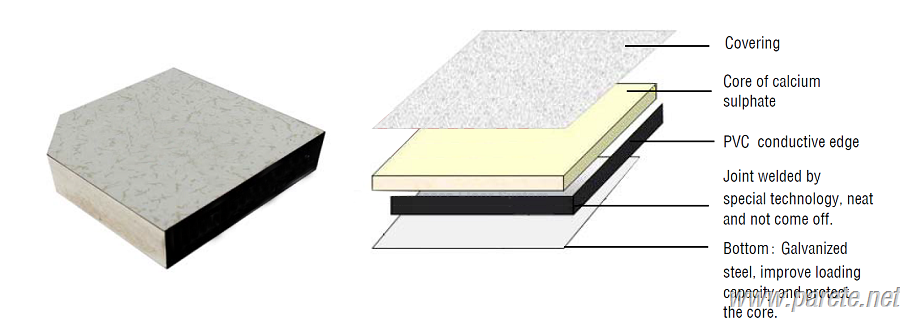

CALCIUM SULPHATE RAISED FLOOR

Calcium sulphate anti-static raised access floor panel is made of high-strength calcium sulphate core. The top surface is stuck with High Pressure Laminate (HPL) or PVC or ceramic, the bottom is covered with aluminum foil or galvanized steel sheet. Four edges are sealed with black PVC edge trim.

Advantages:

- High loading capacity, and conductivity.

- Calcium sulphate core, non combustible, class A.

- High evenness and dimensional accuracy, and good interchangeability.

- Good sealing and acoustic,

- Keep stable in different temperature and humidity.

- Environment friendly and free of pollution.

Application areas:

Calcium sulphate anti-static raised access floor is used in the areas that have high standard in antistatic, loading capacity, fire resistance, good evenness and appearance. For example, computer room of bank, cabinet room of telecom, intelligent office, control center of military, and other high standard computer room.

Technical data:

| No. | Dimension | Concentrated Load | Ultimate Load | Uniform Load | Rolling Load | ||||

| mm | Lb | N | Kg | N | N/m2 | N | Deflection | Permanent deformation | |

| PRT-W800 | 600x600x32(40) | 800 | 3550 | 363 | 10650 | 16500 | 2950 | ≤ 2mm | ≤ 0.5mm |

| PRT-W1000 | 600x600x32(40) | 1000 | 4450 | 454 | 13350 | 23000 | 3560 | ≤ 2mm | ≤ 0.5mm |

| PRT-W1250 | 600x600x32(40) | 1250 | 5560 | 567 | 16680 | 33000 | 4450 | ≤ 2mm | ≤ 0.5mm |

| CICAS or BS standarad size panel | Parete can provide the size 24”x24” (610x610mm) access floor panel | ||||||||

| Floor covering | HPL, PVC or Ceramic tile | ||||||||

| Raised height | Normally from 100mm to 1000mm, above 1000mm, it should be in special solution | ||||||||

| Electrical resistance | It will be 10^4 ~ 10^6 when use the PVC coverings | ||||||||